Digital transformation is reshaping the manufacturing industry. It is changing how factories work, making them smarter and more efficient.

In today’s fast-paced world, manufacturers must keep up with new technologies. Digital transformation helps companies stay competitive. It involves using advanced tools like AI, IoT, and big data. These tools can improve production, reduce costs, and increase quality. The shift to digital can seem challenging, but the benefits are worth it.

This blog will explore how digital transformation is impacting the manufacturing industry. We will look at the key technologies involved and the advantages they bring. Join us as we dive into this important topic and understand its potential.

Credit: valenta.io

Introduction To Digital Transformation

Digital transformation means using technology to change business operations. It helps companies work smarter and faster. Many industries now use digital tools. The manufacturing industry is no different.

Digital transformation involves using digital technologies. It improves processes and products. This can include automation, data analytics, and cloud computing. Automation helps machines work without human help. Data analytics uses data to make decisions. Cloud computing stores data online. These tools help businesses stay competitive.

In manufacturing, digital transformation is important. It makes production faster and more efficient. Machines can talk to each other. This is called the Internet of Things (IoT). It helps find problems early. Data from machines can improve quality. Workers can focus on more important tasks. It also reduces costs by cutting waste. Digital tools help keep up with customer demands.

Key Technologies

IoT connects machines and devices in a factory. This helps in real-time monitoring. Factories use smart sensors to collect data. They can predict issues before they happen. This saves time and money. Smart factories also improve production quality. They can adjust processes automatically. This makes the factory more efficient.

Artificial Intelligence (AI) helps in decision making. It can analyze large amounts of data quickly. This helps in finding patterns and making predictions. AI can optimize production by reducing errors. It also helps in quality control. AI systems can learn from data. They improve over time. This leads to better performance in factories.

Credit: www.airswift.com

Benefits Of Digital Transformation

Digital tools can make tasks faster. Machines work with less downtime. This means more products in less time. Workers can focus on important jobs. Data helps to find and fix problems quickly.

Smart technology checks products. This ensures fewer mistakes. Quality control becomes better. Products meet high standards. Customers get better items. This builds trust and loyalty.

Challenges And Solutions

Data security is a big issue in manufacturing. Hackers can steal important information. This can cost companies a lot of money. It also damages their reputation. Using strong passwords is a good start. Regular software updates help too. It’s important to train employees on security. They should know the risks. They should also know how to spot suspicious activity. Companies must use encryption to protect data. Firewalls and antivirus software are also very important. Together, these steps can reduce risks.

Training workers is a key part of digital change. New tech needs new skills. Without training, workers can’t use new tools well. This slows down the whole process. Training should be ongoing. It should cover all new tools and software. Hands-on practice is very helpful. It makes learning easier. Online courses can also be useful. They allow workers to learn at their own pace. Investing in training benefits everyone. Workers feel more confident. The company sees better results.

Credit: www.themanufacturer.com

Future Of Manufacturing

Smart factories are becoming more common. These factories use advanced technology. Robots and AI help in production. They make processes faster and more accurate. 3D printing is another trend. It allows creating parts quickly. Custom designs are easier to make. Internet of Things (IoT) connects machines. This helps in monitoring and maintenance. Factories are now more efficient and safe.

Manufacturing jobs will change. New skills will be needed. Workers will need to learn about technology. Automation will handle repetitive tasks. This can free workers for creative jobs. Production costs may go down. This can make products cheaper. Sustainability is also important. Eco-friendly practices will grow. This benefits the environment. Digital transformation will make the industry stronger.

Frequently Asked Questions

What Is Digital Transformation In Manufacturing?

Digital transformation in manufacturing involves using digital technologies to improve processes and efficiency.

Why Is Digital Transformation Important In Manufacturing?

It helps reduce costs, improve product quality, and increase production speed. Essential for competitiveness.

How Can Digital Transformation Improve Manufacturing Processes?

It automates tasks, enhances data analysis, and streamlines operations. Results in better decision-making and efficiency.

What Technologies Drive Digital Transformation In Manufacturing?

Key technologies include IoT, AI, robotics, and cloud computing. They integrate and optimize manufacturing systems.

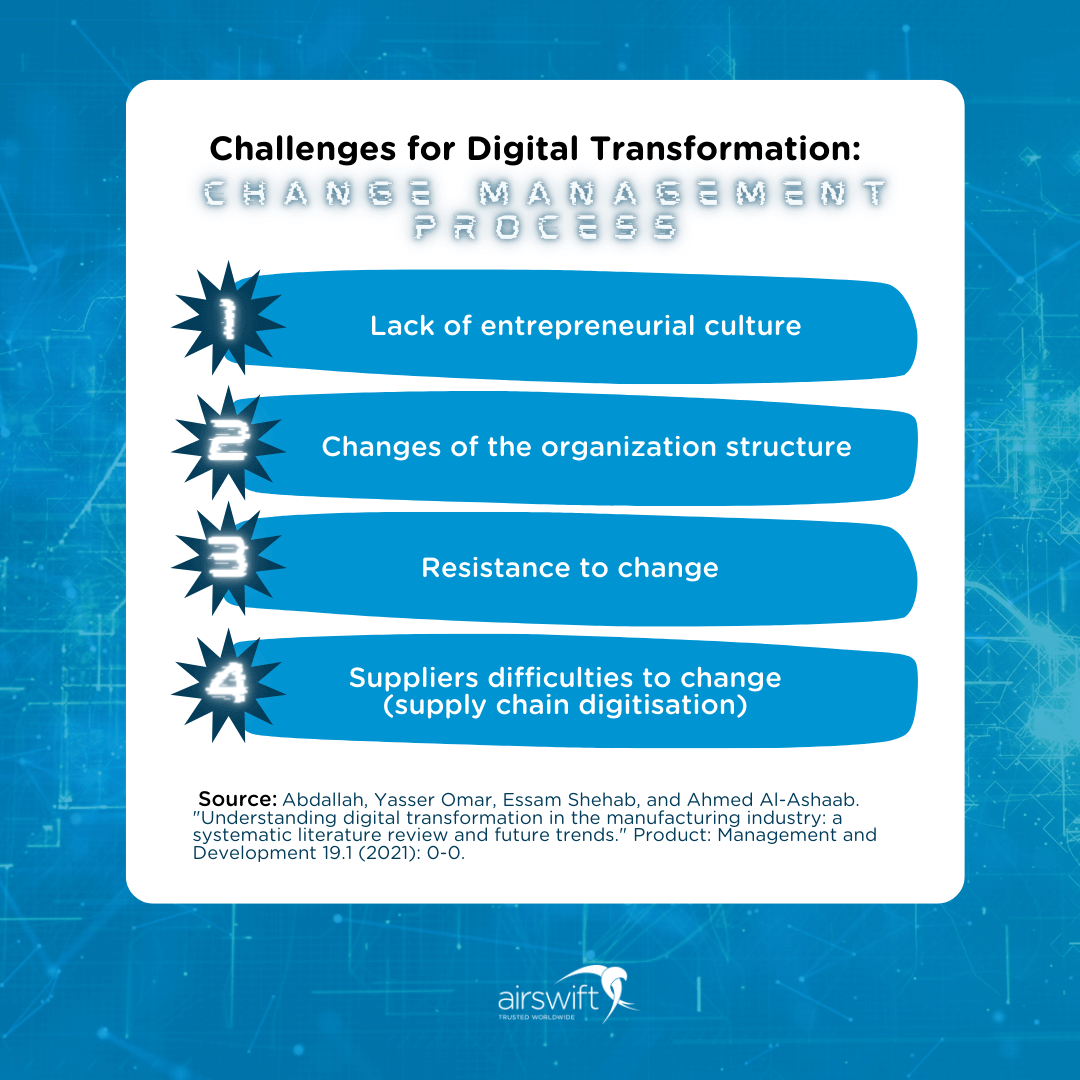

What Are The Challenges Of Digital Transformation In Manufacturing?

Challenges include high costs, cybersecurity risks, and need for skilled workers. Requires careful planning and execution.

Conclusion

Digital transformation reshapes the manufacturing industry. It brings increased efficiency and productivity. Companies benefit from smart technologies and data-driven decisions. The future of manufacturing looks promising with these advancements. Adapting to changes is key for success. Stay updated and embrace innovations.

The journey may be challenging, but the rewards are substantial. Start small, think big, and move forward. Manufacturing will continue evolving with technology. Keep learning and improving. Your efforts will pay off.

Sufiya Begom is a Passionate Digital Innovator and the Visionary Founder of the Dynamic Platform, Digital Pro Info. With a deep-rooted enthusiasm for digital technologies, Sufiya has built a comprehensive space that offers valuable insights into digital products, reviews, guides, software, and sales, empowering individuals to make informed decisions in the ever-evolving digital landscape.